Do steel wire ropes need to have ductility?

Time:2018-05-29 13:52:35Click:

Steel wire rope rigging, with its high strength and toughness, has become a commonly used tool in lifting, towing,tensioning and other operations. Whether it needs to possess ductility remains a persistent concern among many practitioners.

In terms of material, any substance has ductility. However,the tensile stress-strain curves vary across different specifications and manufacturing processes of wire rope slings. As operational tools, we must first strictly control the elastic stress range during production, calculate the maximum stress value that can be borne in advance, and then determine the production process based on this, so that the ductility of the rigging is safe and controllable, and avoid excessive stretching from affecting the stability of the job.

In practical applications,steel wire ropes are rarely used alone and often participate in operations in complex structural combinations. This requires us to analyze the influence of stress conditions on the ductility of the rigging from a mechanical perspective. During operations, the rigging needs to have a certain degree of ductility: When lifting heavy objects, if suddenly subjected to external impact, the rigging lacking ductile characteristics will directly bear excessive instantaneous tensile stress, which can easily exceed the ultimate bearing capacity of the rigging and cause the risk of fracture. Rigging with reasonable ductility can buffer instantaneous stress through elastic stretching, significantly reducing the probability of fracture and providing an important guarantee for operational safety.

Hot Sale

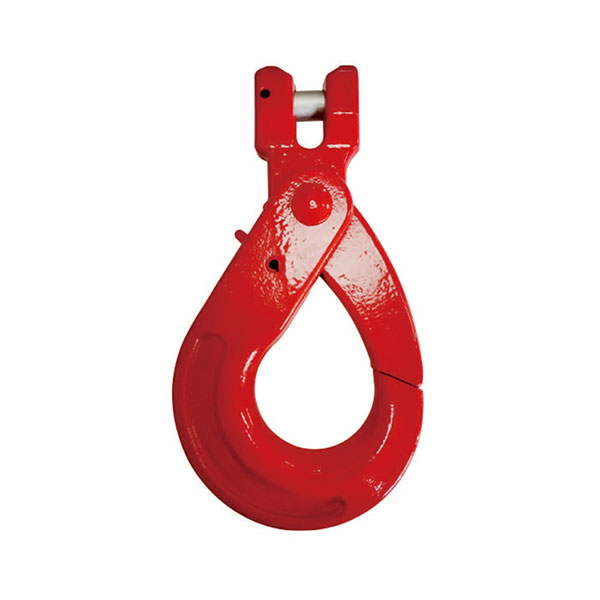

Hot Sale G80 Clevis Self Locking Hook

G80 Clevis Self Locking Hook Mold Lifting Lugs 2133.12 Series

Mold Lifting Lugs 2133.12 Series G80 Alloy Steel Extension Rods for Lifting Eyebolt

G80 Alloy Steel Extension Rods for Lifting Eyebolt PC Series G80 Alloy Steel Lifting Eyebolt

PC Series G80 Alloy Steel Lifting Eyebolt PE Series G80 Swivel Lifting Eyebolt

PE Series G80 Swivel Lifting Eyebolt PA Series G100 Universal Swivel Lifting Eyebolt

PA Series G100 Universal Swivel Lifting Eyebolt