Maintenance of lifting tackle

Time:2018-06-05 12:03:06Click:

(1) During the use of the lifting tackle, if the lock rotates inflexibly or fails to engage properly, the adjusting nut should be checked first, followed by an examination of the following components:

① Check if the tension spring of the pawl is damaged, replace it immediately if damage is found;

② Check if the transmission mechanism is jammed, if jamming is caused by insufficient lubrication, apply lubricating oil (or grease) to the moving joints of the transmission mechanism.If the guide pin is too tight, loosen the nut appropriately. If the connection is loose or the transmission pipes /other rods are deformed, correct the issue promptly;

③ Check if the extension of the buffer spring is insufficient; if so, shorten the length of the steel wire rope connected to the buffer spring.

(2) During use,prevent the indicator marking paint on the lifitng tackle's indicator board from peeling off .If peeling is found,repaint the original indicator markings in a timely manner.

(3) Clean the steel wire rope of the lifiting tackle regularly and apply lubricating oil or grease promptly, especially to the bent sections of the steel wire rope.

(4) Under normal use conditions, the main load-bearing components (including lifting rings, rotary locks, lug plates and rigging shackles) shall be inspected at least once every 3 months to ensure there are no cracks or severe deformation.

(5) All oil cups ,including those on ratchet mechanism, sliding bearing seats and rotary lock boxes, shall be filled with lubricating oil at the main moving joints as required based on usage conditions.

(6) Regularly check for loose rope clips and overstretched buffer springs, and address any issues in a timely manner.

(7) No type of lifting tackle shall be used beyond its rated lifting capacity, and the buffer spring must not be overstretched.

(8) The hoisting process should be stablized to prevent deformation caused by collisions between the lifitng tackle and the crane or other equipment.

Hot Sale

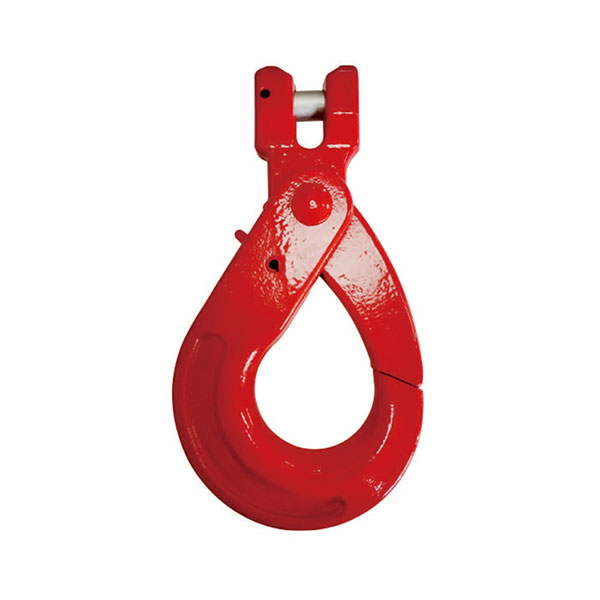

Hot Sale G80 Clevis Self Locking Hook

G80 Clevis Self Locking Hook Mold Lifting Lugs 2133.12 Series

Mold Lifting Lugs 2133.12 Series G80 Alloy Steel Extension Rods for Lifting Eyebolt

G80 Alloy Steel Extension Rods for Lifting Eyebolt PC Series G80 Alloy Steel Lifting Eyebolt

PC Series G80 Alloy Steel Lifting Eyebolt PE Series G80 Swivel Lifting Eyebolt

PE Series G80 Swivel Lifting Eyebolt PA Series G100 Universal Swivel Lifting Eyebolt

PA Series G100 Universal Swivel Lifting Eyebolt