Overview of the hook

Time:2018-06-05 12:02:46Click:

Lifting hooks are classified by shape into single hooks and double hooks; by manufacturing method, they are categorized as forged hooks and laminated hooks.

Single hooks are simple to manufacture and easy to use, but their force-bearing performance is poor. They are mostly used in general woking conditions with lifting capacities below 80 tons. Double hooks with symmetrical force distribution, are often employed for heavy lifting operations with large capacities. Laminated hooks are riveted from numerous shaped steel plates.Even if the individual plate cracks, the entire hook will not fail,offering high safety. However,their substantial weight makes them suitable primarily for cranes with large lifting capacities or for transporting molten steel ladles.

Lifting hooks are frequently subjected to impact during operation and must be made of high-quality carbon steel with good toughness.

Lifting hooks are available in a wide variety, generally including: shackles, lifting rings, round rings, pear-shaped rings, long lifting rings, combination lifting rings, S-hooks, nose hooks, American hooks, clevis hooks, eye hooks, lifting eyebolts with safety latches, chain shackles, etc. These products feature unique, innovative, high-quality, and safe characteristics, and are applicable to factories, mines, oil fields, chemical plants ,docks and other industries. Ensuring safety and quality with a static load safety factor of up to 3 times,and their lifting capacity ranges from 5 tons to 150 tons.

Hot Sale

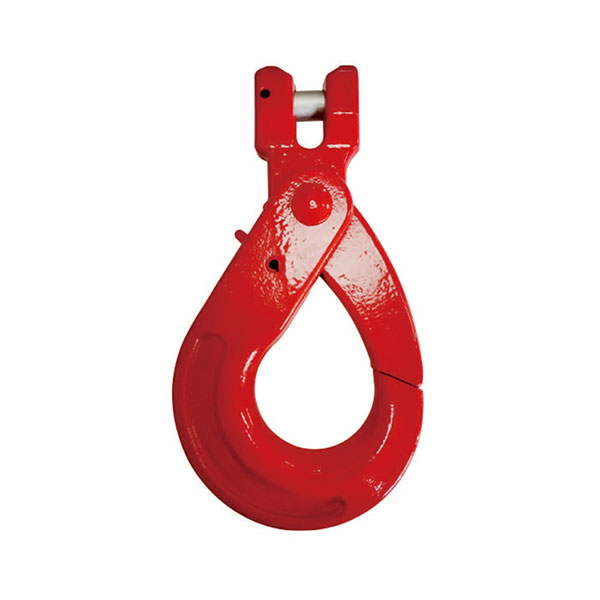

Hot Sale G80 Clevis Self Locking Hook

G80 Clevis Self Locking Hook Mold Lifting Lugs 2133.12 Series

Mold Lifting Lugs 2133.12 Series G80 Alloy Steel Extension Rods for Lifting Eyebolt

G80 Alloy Steel Extension Rods for Lifting Eyebolt PC Series G80 Alloy Steel Lifting Eyebolt

PC Series G80 Alloy Steel Lifting Eyebolt PE Series G80 Swivel Lifting Eyebolt

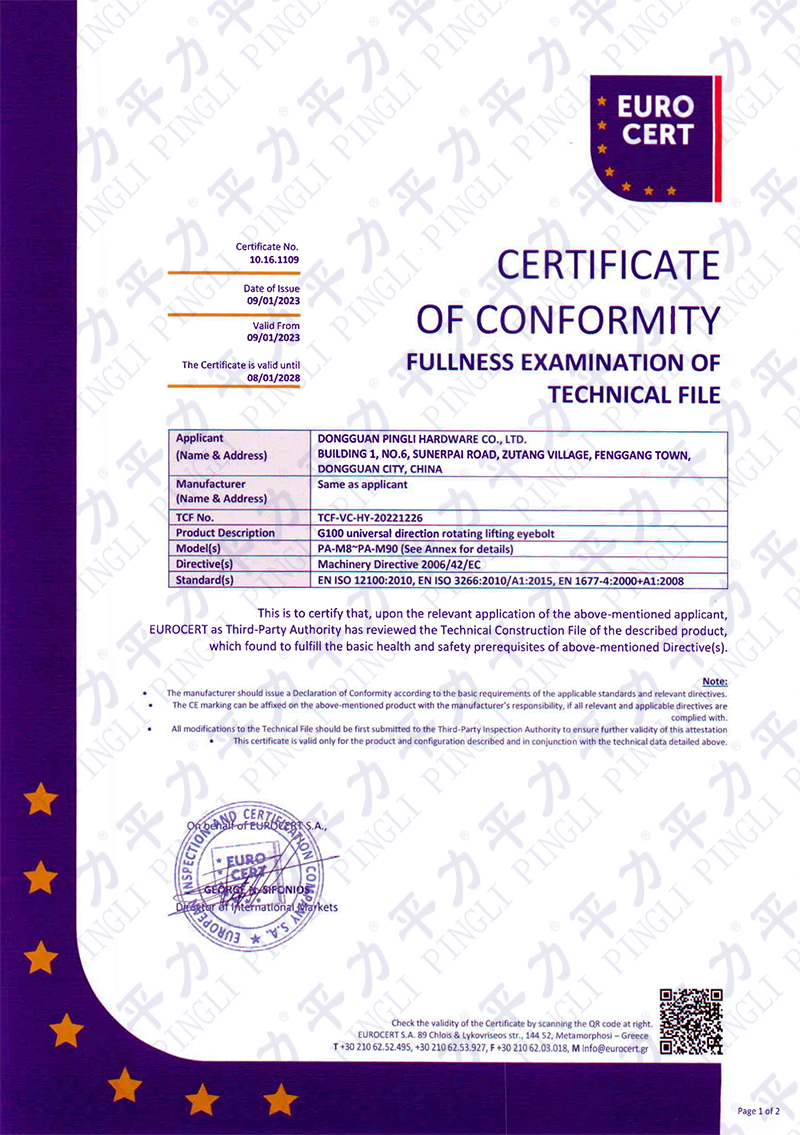

PE Series G80 Swivel Lifting Eyebolt PA Series G100 Universal Swivel Lifting Eyebolt

PA Series G100 Universal Swivel Lifting Eyebolt