User Instructions

● Ensure the tapped hole has sufficiently threaded length to engage the eyebolt shank fully;

● The eyebolt thread shall be securely fastened and tightly fitted to the contact surface (Tighten manually; no tools shall be used for fastening);

● When the loading ring is oriented for vertical lifting direction, the maximum load capacity can reach.

● The eyebolt can rotate under rated load. However, it is not suitable for permanent rotation at full load in 90°direction.

● Strictly follow the operation manual during use.

Acceptance Procedures

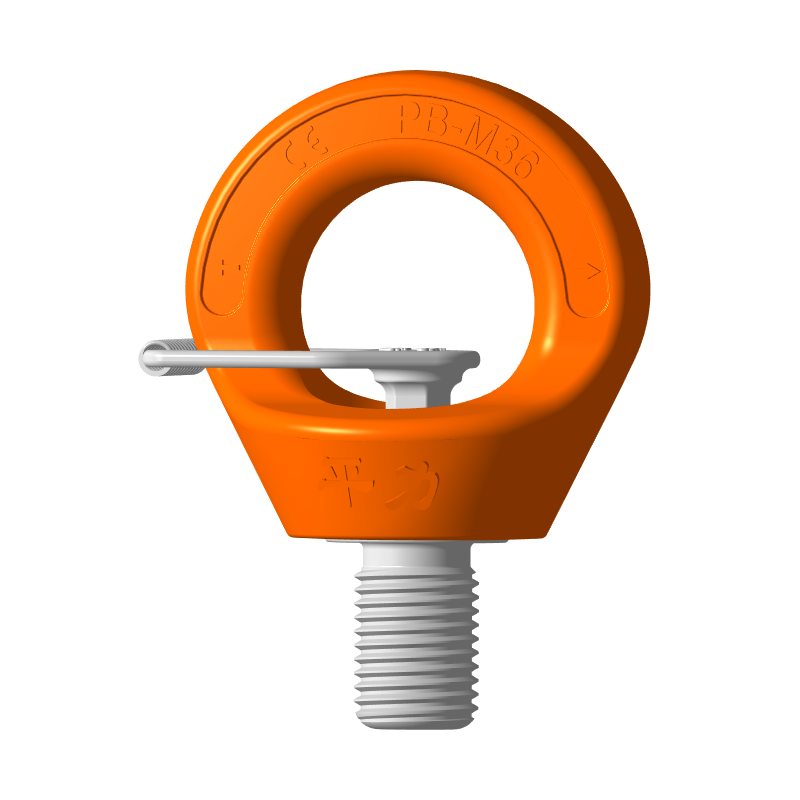

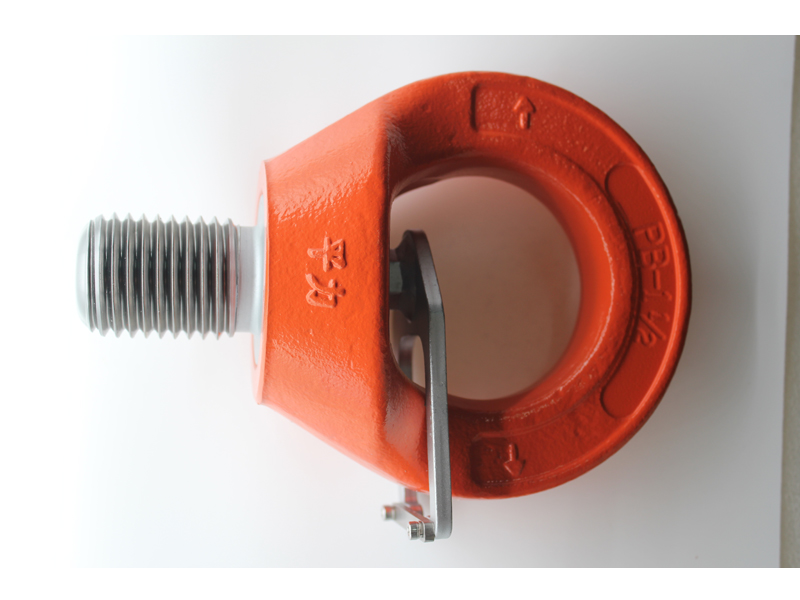

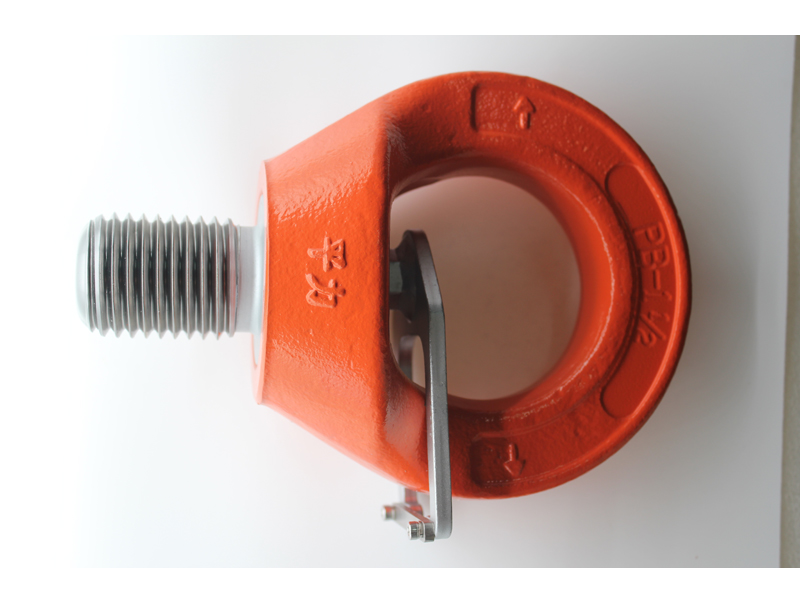

1. The overall dimensions shall comply with the corresponding standards to ensure there are no cracks or defects, and its specifications, working load limit and material code shall be clearly marked on the eyebolt surface;

2. Acceptance of thread: visually inspect threads are full and free of scratches or impacts,test with the thread ring gauges (go/no-go gauge) to ensure accuracy of 6g.

3. The thread axis of the eyebolt must be perpendicular to the bearing surface. Rotate a go gauge to fit the thread root with the contact surface without clearance,that is, the perpendicularity is acceptable;

4. Acceptable eyebolts shall be provided with a manufacturer's certificate or a detailed written testing report for filing.

Usage Restrictions

1. Operating temperature range: - 40 ℃ to 400 ℃ (please consult the manufacturer for use beyond 200 ℃);

2. Eyebolts should not be immersed in acidic solutions or exposed to acid fumes or other chemicals.For any application in a chemical environment, please contact the Technology Department of PINGLI.

3. Warning: Do not exceed the maximum safe working load.

Precautions for Installation and Operation

1. The maximum lifting capacity (working load limit) of the eyebolt is only applicable when the eyebolt is installed on steel, cast steel or non-cast iron workpieces for operation;

2. The contact surface around the tapped hole must be kept flat,and the drilling depth shall be sufficient to fully secure the bolt in position;

3. The eyebolt must be screwed in until the bearing surface is tightly fitted, but no tools are allowed to apply force for tightening; if not screwed in place, the eyebolt will be deformed or fractured;

4. Please lift in accordance with the angles corresponding to the WLL of the eyebolt. The eyebolts must be installed in different positions according to different lifting methods and do not move the center of gravity during lifting.

5. Please strictly install the eyebolts for lifting according to the number of designed lifting points on the workpiece, and do not reduce the number of lifting points for lifting.

6. Use slow lifting during hoisting to avoid rapid impact lifting.

7.It is strictly forbidden to operate in violation of regulations,including:

● Altering the structure of the eyebolt;

● Subjecting the eyebolt to lateral force;

● The eyebolt is obviously deformed or severely worn;

● The thread is damaged;

● The eyebolt is not fitted with the bearing surface;

● Lifting method is not within the marked range.

Maintenance and Periodic Examinations

1. Enterprises are required to conduct an internal safety inspection quarterly each year and keep inspection records;

2. A thorough examination shall be conducted by competent person in accordance with national standards annually, if used frequently, the inspection frequency may be increased as propriate and inspection records shall be kept;

3. The eyebolt surface shall be cleaned before inspection to ensure clear examination;

4. Pay attention to signs that may affect safety and functionality, such as: thread defects, cracks, grooves, deformation, obvious signs of overheating or the cross-section wear exceeds 10%.

5. If any signs that may affect the safety and functionality of the eyebolt are found during examination, the eyebolt should be scrapped immediately;

6. In case of any doubts or damage to the eyebolt, please stop the operation immediately and request a professional inspection.

Storage

PINGLI lifting products shall be stored in a clean, dry, corrosion-free and oil-free environment. The threads must be properly protected from collision.

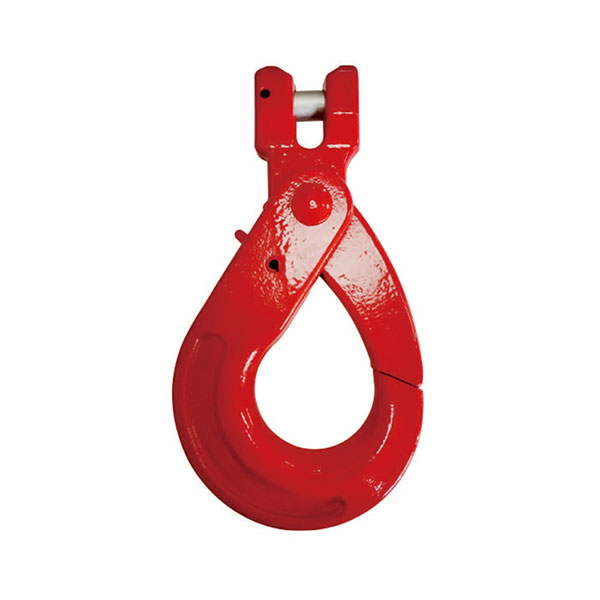

Hot Sale

Hot Sale G80 Clevis Self Locking Hook

G80 Clevis Self Locking Hook Mold Lifting Lugs 2133.12 Series

Mold Lifting Lugs 2133.12 Series G80 Alloy Steel Extension Rods for Lifting Eyebolt

G80 Alloy Steel Extension Rods for Lifting Eyebolt PC Series G80 Alloy Steel Lifting Eyebolt

PC Series G80 Alloy Steel Lifting Eyebolt PE Series G80 Swivel Lifting Eyebolt

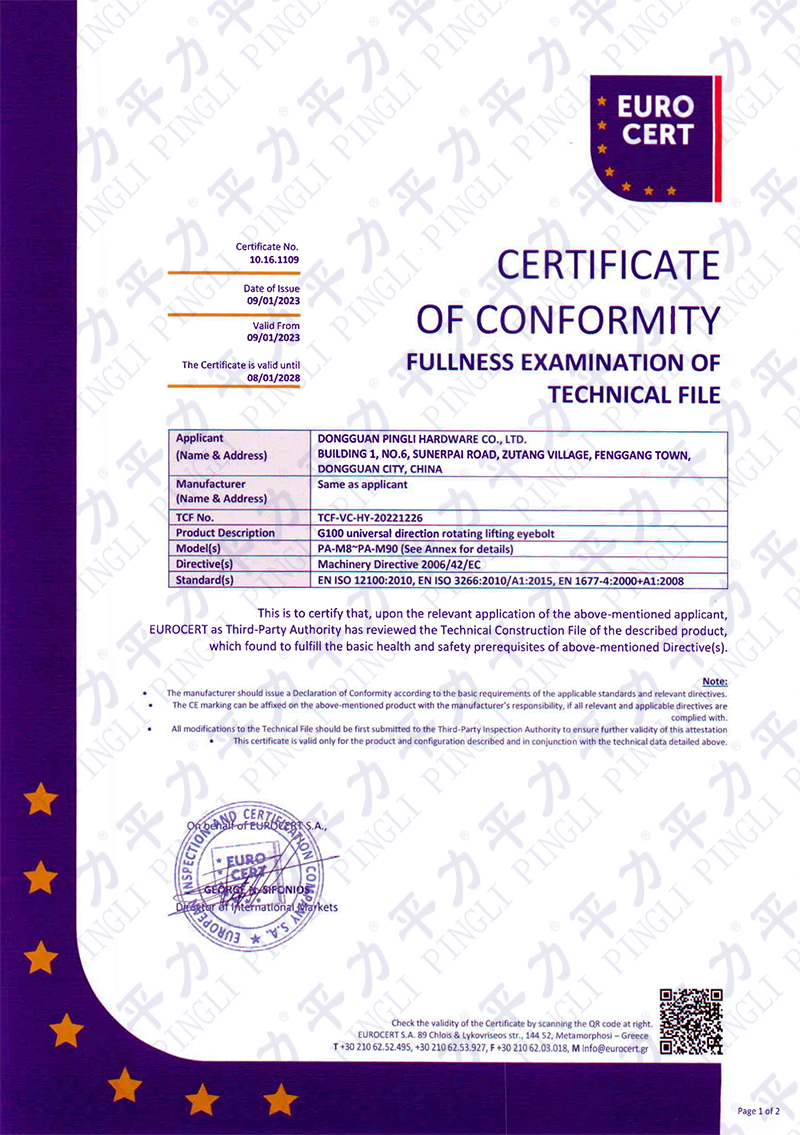

PE Series G80 Swivel Lifting Eyebolt PA Series G100 Universal Swivel Lifting Eyebolt

PA Series G100 Universal Swivel Lifting Eyebolt