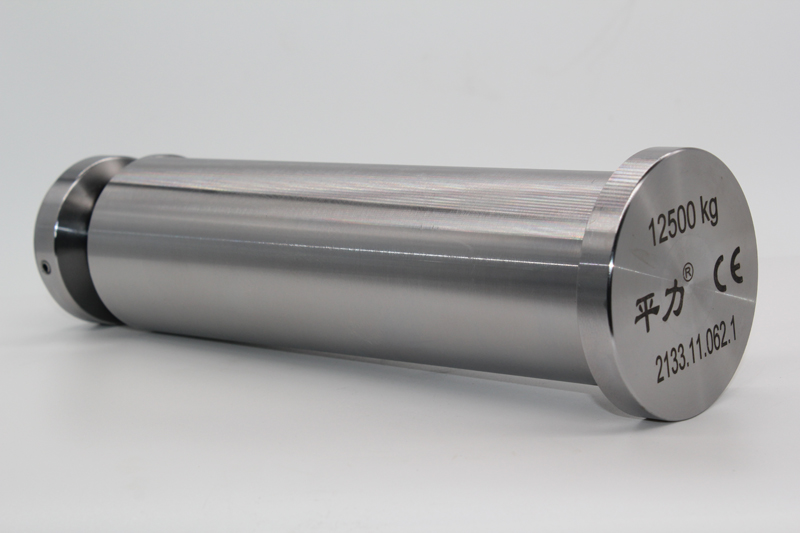

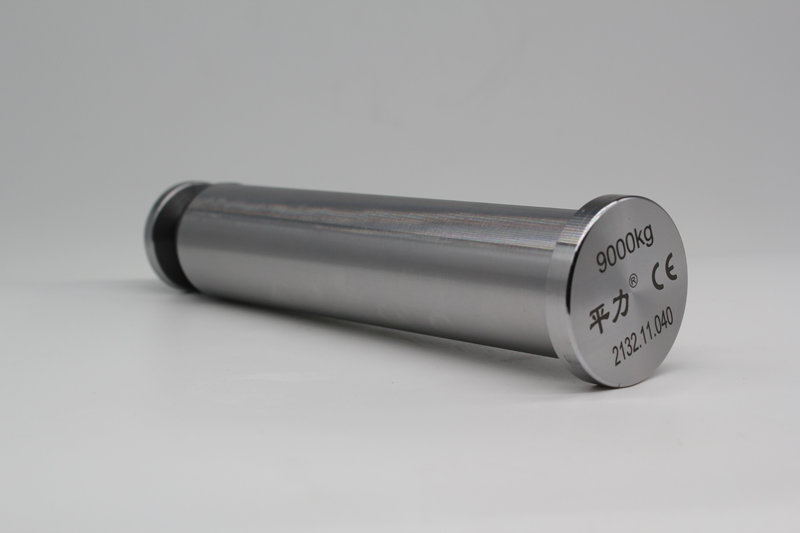

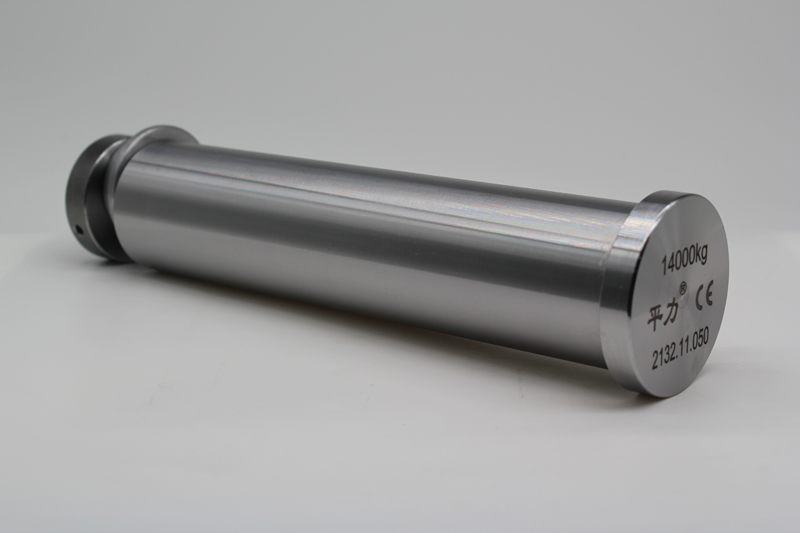

Manufacturing: 42CrMoA alloy steel - heat treatment quenching and tempering

Product Diagrams of Mold Lifting Pin 2133.11 Series, 2133.12 Series, 2132.10 Series, 2132.10.55 Series, 2132.11 Series, B02.10 Series, B02.11 Series, B02.12 Series, B02.30 Series, B02.35 Series, B02.44 Series, B02.45 Series and B02.40 Series

Product Diagram

Hot Sale

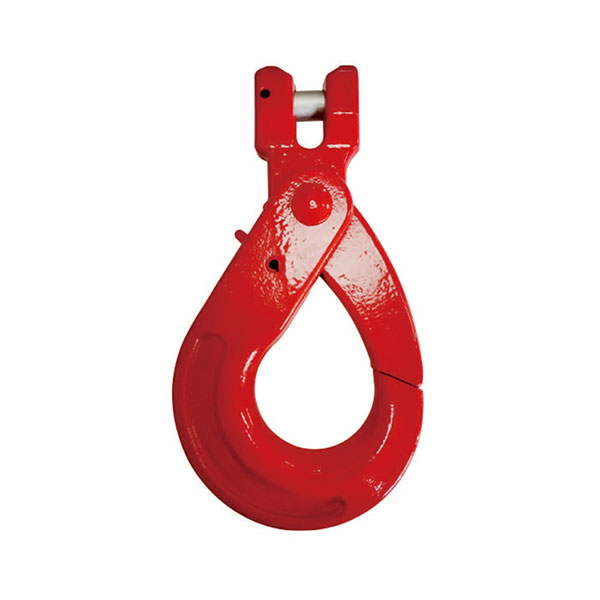

Hot Sale G80 Clevis Self Locking Hook

G80 Clevis Self Locking Hook Mold Lifting Lugs 2133.12 Series

Mold Lifting Lugs 2133.12 Series G80 Alloy Steel Extension Rods for Lifting Eyebolt

G80 Alloy Steel Extension Rods for Lifting Eyebolt PC Series G80 Alloy Steel Lifting Eyebolt

PC Series G80 Alloy Steel Lifting Eyebolt PE Series G80 Swivel Lifting Eyebolt

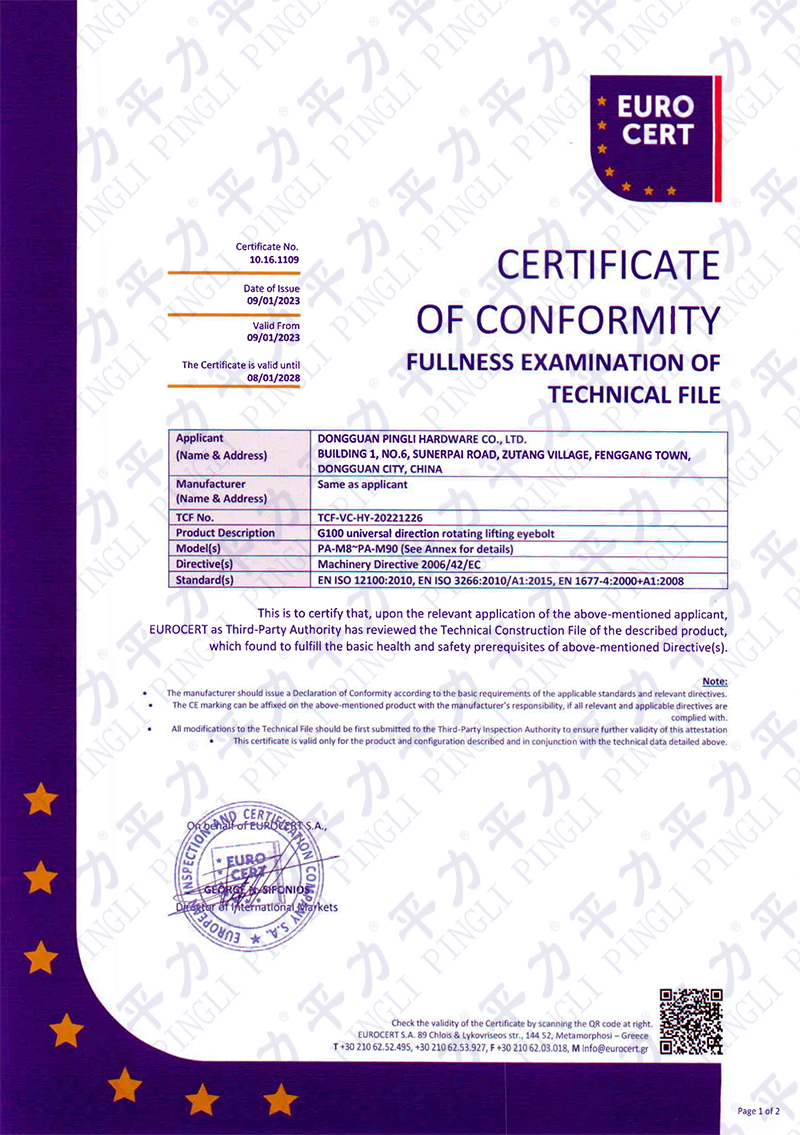

PE Series G80 Swivel Lifting Eyebolt PA Series G100 Universal Swivel Lifting Eyebolt

PA Series G100 Universal Swivel Lifting Eyebolt