Rust prevention of steel wire rope rigging

Time:2018-06-05 12:02:00Click:

Wire rope rigging is made from steel wire rope through processing. It is primarily employed for lifting, towing, tensioning, and load-bearing, and is also referred to as a "rope".Light steel wire rope features high strength, light weight, flatness, and resistance to sudden breakage or brittleness, and is widely used in the steel, chemical, transportation, and port industries. Common types include phosphate-coated steel wire ropes, galvanized steel wire ropes, stainless steel wire ropes and smooth metal wire ropes.

In the workplace, galvanized steel wire rope can be used as a raw material to enhance rust resistance in wet or outdoor environments.

The wear of steel wire rope slings is mainly attributed to the gradual breakage caused by metal fatigue from bypass hooks and the repeated bending of the cranes. Besides hanging or pausing operations, the diameter ratio of the wire rope is a key factor determining the service life of the sling.

Steel wire ropes should be discarded when surface wear , internal corrosion, or the number of broken wires per strand exceeds specified values.

Steel wire ropes are mainly used for lifting, pulling, and other high-strength hoisting operations that require heavy load transportation. It is strictly prohibited to use them under the crane frame or on objects behind the crane.

Hot Sale

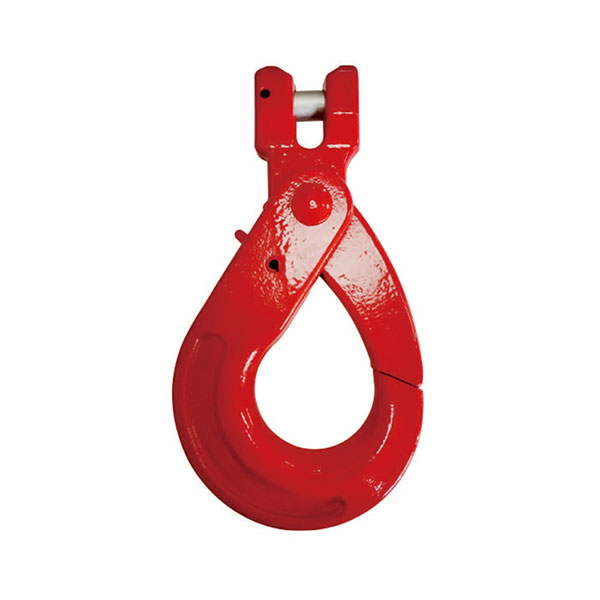

Hot Sale G80 Clevis Self Locking Hook

G80 Clevis Self Locking Hook Mold Lifting Lugs 2133.12 Series

Mold Lifting Lugs 2133.12 Series G80 Alloy Steel Extension Rods for Lifting Eyebolt

G80 Alloy Steel Extension Rods for Lifting Eyebolt PC Series G80 Alloy Steel Lifting Eyebolt

PC Series G80 Alloy Steel Lifting Eyebolt PE Series G80 Swivel Lifting Eyebolt

PE Series G80 Swivel Lifting Eyebolt PA Series G100 Universal Swivel Lifting Eyebolt

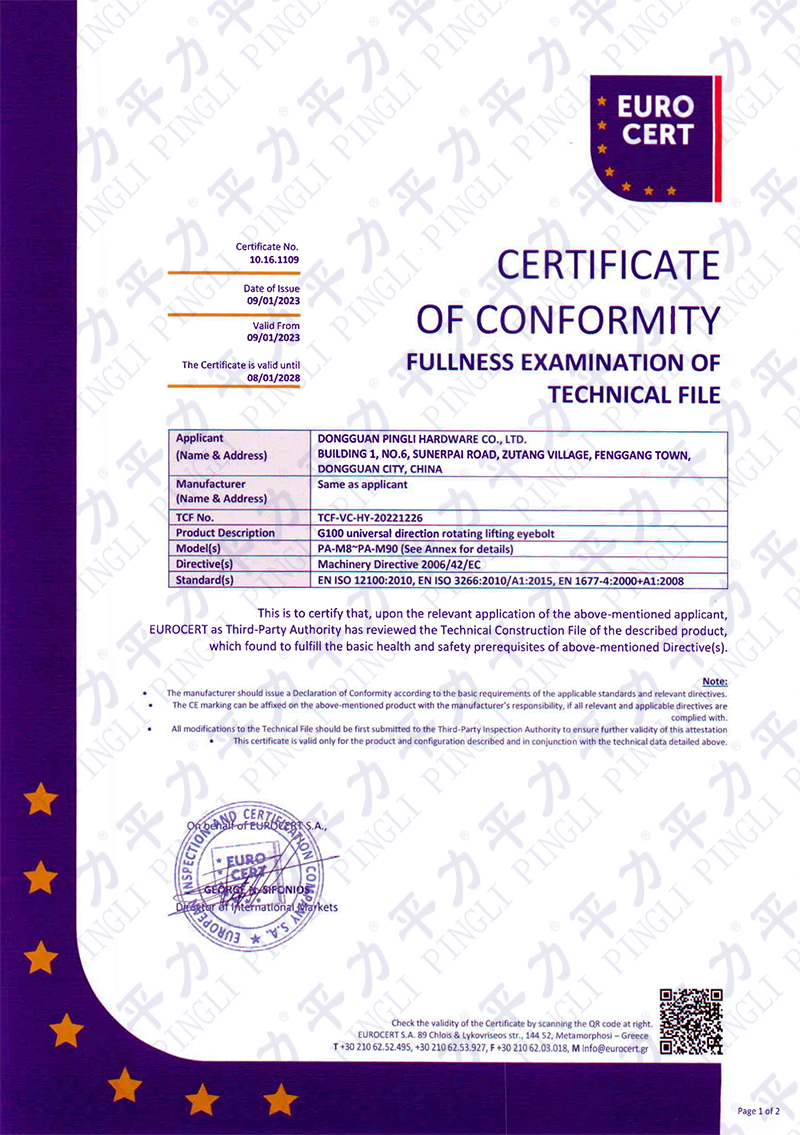

PA Series G100 Universal Swivel Lifting Eyebolt